1. Introduction to Process Engineering.

2. Introduction to mining engineering.

3. Hydrocarbons and petrochemical industry.

4. Hygiene and safety.

1. Introduction to Process Engineering

Since the middle of the 19th century, applied chemistry and then “industrial chemistry” has been considered as part of the body of knowledge that chemistry as a science represents.

It brings together all the technical but also economic, energy and environmental data concerning the manufacturing processes of a large number of industrial products, whether strictly chemical of synthetic origin or not (styrene, PET, pharmaceutical active molecules, gas air, sulfur, etc.) or whether they are derived from processes related to the chemical industry (plasters, starch, nuclear fuels, electronic components, paints or formulated adhesives, etc.)

Process engineering is a younger discipline. Originally, in the USA (early 20th century), it was called “chemical engineering”. It is none other than chemical engineering each time it is applied to material transformation process industries other than the chemical industry.

Process engineering is the set of concepts and methods making it possible to design, size, optimize and even conduct all material transformation processes, whether it involves producing plastics, medicines, drinking water, special steels, energy...or treat effluents.

Chemical engineering thus allows the transition from a laboratory synthesis to an industrial process as well as its operation while respecting economic, technical, environmental and safety constraints.

The Objective of the process engineering specialist

The process engineering or chemical engineering engineer is involved in setting up the installations and their validation. It must take into account, among other things, all aspects of reliability, security and ergonomics of the systems.

Engineers in process engineering and chemical engineering can be found in all sectors of activity in chemistry, parachemistry (cosmetics, paints, adhesives, materials, agrochemistry, glass, plastics processing, elastomers, etc.) and other sectors (pharmacy). , energy, automobile, aeronautics, nuclear, petroleum, plastics, rubber, materials, environment, etc.).

2. Introduction to Mining Engineering

A mine is an exploited deposit of materials (e.g. gold, coal, copper, diamonds, iron, salt, uranium, etc.).

Mining Engineering:

· Mining exploitation,

· Exploitation of technologies and management methods of associated industries, namely production/transformation of energy and raw materials.

Mine exploitation poses many problems, and therefore involves many fields of science:

· Prospecting, earthworks, Wells & galleries, retaining, loading, rolling, extraction, lighting, dewatering, ventilation, etc.

This is the reason why in most countries specific engineering schools, mining schools, have been created.

Mining engineering training

Training in the mining engineering field covers:

· Geosciences (Geology, Geophysics, Petrography, Geostatistics);

· Mathematics, Computer Science;

· Rock mechanics, Geomechanics;

· Exploitation of open-cast and underground mines;

· Mineral valorization and processing;

· Land Control and Geo Engineering;

· Digital design and modeling (CAD, CAD);

· Security, Economy and Business Management;

Area of intervention

The main areas of intervention of the mining engineer concern:

· The open-air and underground extractive industry,

· The development of extracted mineral substances,

· Planning, operation, and management of mines.

· It is also used in various sectors of public works and civil engineering such as earthworks, basic infrastructure and engineering structures (bridges, tunnels, railways, dams, etc.), land control and georisks.

Opportunities

The mining sector offers excellent job prospects both nationally and internationally, engineers work in the different sectors of mining, civil engineering, public works, public administrations (Ministries, Control Agencies ), private sector, consulting and materials analysis and testing laboratories, research centers.

Employers

1. Public administration ;

2. Research centers ;

3. Mining companies ;

4. Mining Equipment Companies ;

5. Consulting engineering firms ;

6. Financial institutions ;

7. Processing plants.

Hydrocarbons and Petrochemical industry

Oil

Crude oil is a heterogeneous mixture of various hydrocarbons (molecules composed of carbon and hydrogen atoms), unusable as is. Its components must be separated in order to obtain the final products that can be used directly. There are generally two main types:

· Energy products, such as gasoline, diesel or fuel oil;

· Non-energy products, such as lubricants, bitumen and naphthas used in petrochemicals.

ORIGIN

Hydrocarbons (CnHm) constitute a source of fossil energy: Oil, natural gas, shale gas.

Fossil fuels are rich in carbon in the form of hydrocarbons, they come from the methanization of decomposing biological beings and buried in the ground for several million years.

These are energies which are therefore not renewable, in the same way as nuclear energy, because their natural reconstitution requires a long time to be reformed and because they are used faster than the time necessary for the recreation of reserves.

The exploitation of these fuels is at the origin of environmental problems relating to ecological disturbances linked to their extraction and their use, with global warming which would be responsible for greenhouse gases such as CO2 emitted by their combustion.

Oil refinery

Oil refining is an industrial process that transforms crude oil into different products such as gasoline, heavy fuel oil or naphtha.

Refining consists of separating the various cuts of petroleum and transforming them into intermediate and commercial products.

Petrochemicals

Petrochemistry is the science concerned with the use of basic chemical compounds from petroleum to manufacture other synthetic compounds which may or may not exist in nature; in the latter case, these compounds are called artificial. These fabrications are, in general, based on appropriate chemical reactions in the presence or absence of a catalyst. For example, during petroleum refining, the naphtha cut from atmospheric distillation can serve as feedstock for a steam cracking (or steam cracking) unit.

This naphtha can be cracked in a steam cracker, and produces unsaturated, fragile products that can be transformed into plastics and other cosmetic and pharmaceutical products. This is how from oil we can manufacture plastic materials of all kinds which are then used as raw materials in the construction sectors and in the electrical, electronic, textile, aeronautics and other industries.

Hydrocarbon exploitation

Four stages in the hydrocarbon exploitation process:

1. Production

· Extraction - Drilling - Off shore.

2. Transportation

· (Oil pipeline, gas pipeline, pumping or compression station).

3. Treatment

· Refining: extraction of by-products ;

· Liquefaction.

4. Operation & Marketing.

· Extraction- Oil ;

· Gas Extraction.

Pipeline Transportation

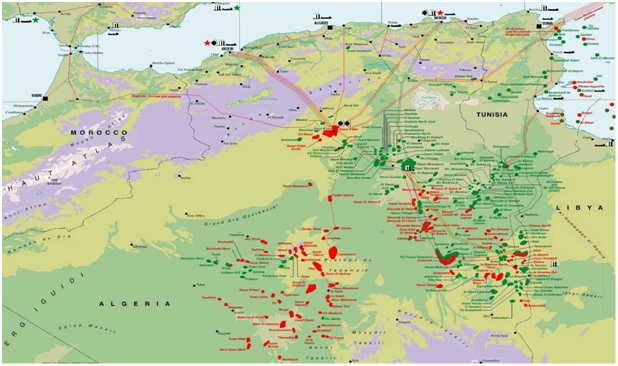

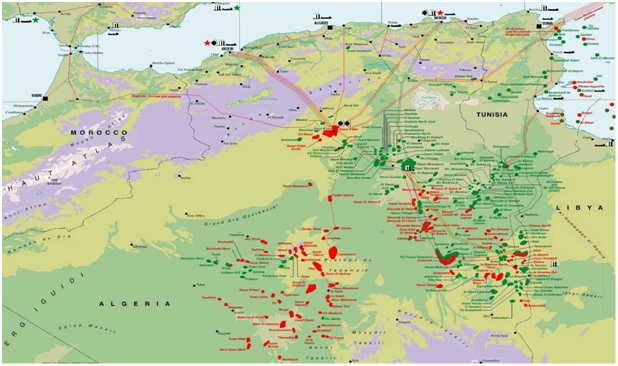

The Pipeline Transport Activity (TRC) ensures the transport of hydrocarbons (crude oil, condensate, LPG and natural gas) and has a pipeline network of nearly 19 623 km in 2015 compared to 14 915 in 2005, i.e. increase of 4 708 km:

16 gas pipelines with a length of 9,677 km, with diameters varying mainly between 40” and 48” with a capacity of 178 billion m3/year.

21 oil pipelines with a length of 9,946 km, with diameters varying mainly between 20” and 34” and a capacity of 248 Million Toe/Year.

a. Enrico Matei, connecting Algeria to Italy via Tunisia ;

b. Pedro Duran Farrel, connecting Algeria to Spain via Morocco ;

c. Hassi R’Mel - Béni-Saf, connecting Algeria to Spain (Almeria) via Medgaz.

Pumping & Compression Stations

· Sonatrach has 82 pumping and compression stations equipped with more than 290 main rotating machines with a total power of nearly 03 million HP ;

· Turbopumps for the pipelines of the Oil pipeline circuit ;

· Turbocompressors for gas pipeline circuit pipes.

Gas Compression Station

GR-5 Hassi – Rmel

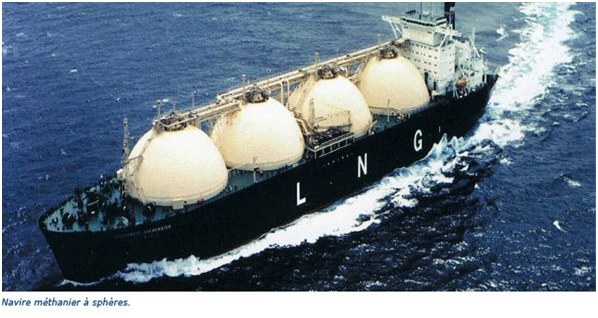

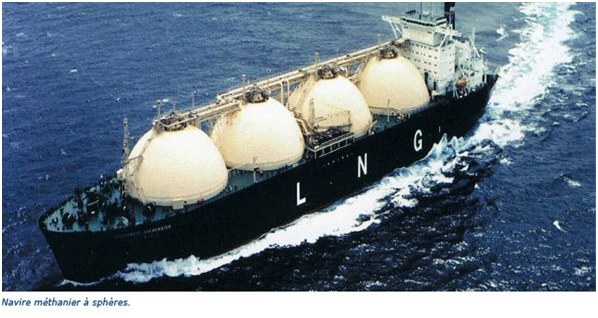

Transportation By Sea

Distillation

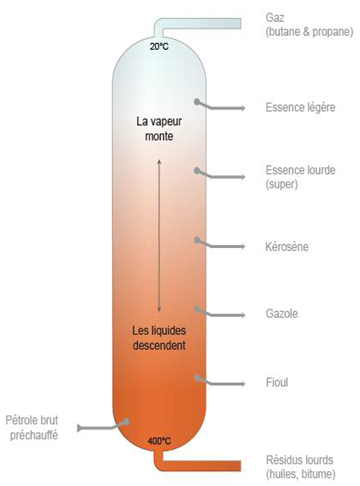

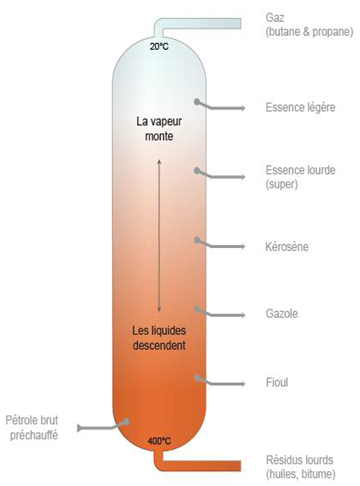

Atmospheric distillation of crude oil, at a pressure close to that of ambient air, separates it into different petroleum cuts. Under the effect of heat, the lightest and most volatile products, such as butane, propane and light gasolines, rise to the top of the distillation column where they are collected. Others will be at different levels of this column: heavy gasoline, kerosene, diesel cuts and domestic fuel oil. The residue, or heavy fuel oil, is extracted at the bottom of the column.

A second distillation, under vacuum, of these residues makes it possible to recover more diesel. The residue obtained at the bottom of the column then no longer contains diesel or light products. It is used in the manufacture of bitumen and heavy fuel oils.

Conversion processes

Different conversion processes make it possible to modify the chemical structure of petroleum cuts resulting from distillations. Thus, catalytic cracking breaks down heavy molecules under the action of a catalyst and a high temperature (around 500°C) to transform them into lighter products: gases, gasolines and diesel fuels. Hydrocracking follows the same principle but allows, with the addition of hydrogen, to produce sulfur-free diesel. Deep conversion processes, such as coking, make it possible to further increase the production of light hydrocarbons from heavy fuel oils.

Steam cracking

Steam cracking is a petrochemical process by which saturated hydrocarbons are broken into smaller, and often unsaturated, molecules. It is therefore the main source of production of alkenes (ethylene, propylene, etc.), monomers at the origin of many plastic materials.

Hygiene safety

a. Definition and different axes of the HSE sector.

b. Sectors of activity.

c. Role of the specialist and training of the specialist in HSE.